(continued from part 1)

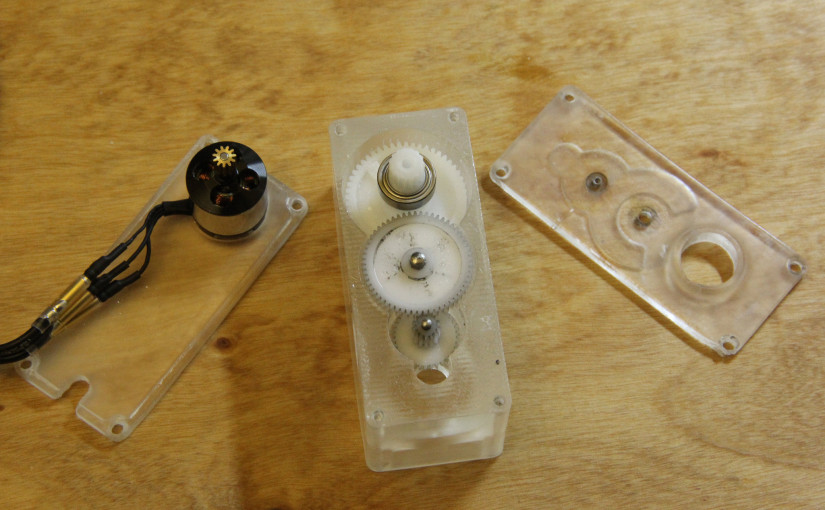

The results are in! I’m thrilled that the Form1+ was able to achieve tolerances tight enough to nail the spacing for 0.4-Module gearing.

The video below is just a brief back-and-forth test of the 60-watt motor.

To get the transmission to run above, I didn’t need to do too many touch-ups, but here’s the breakdown of the adjustments I did make.

- I lightly sanded the lid where the gears rub and added brass washers to each shaft on the other side of each gear.

- The M2 dowel pin shaft slipped into it’s hole a bit too easily after post-curing the case. A dab of Loctite 409 resolved this problem pretty easily.

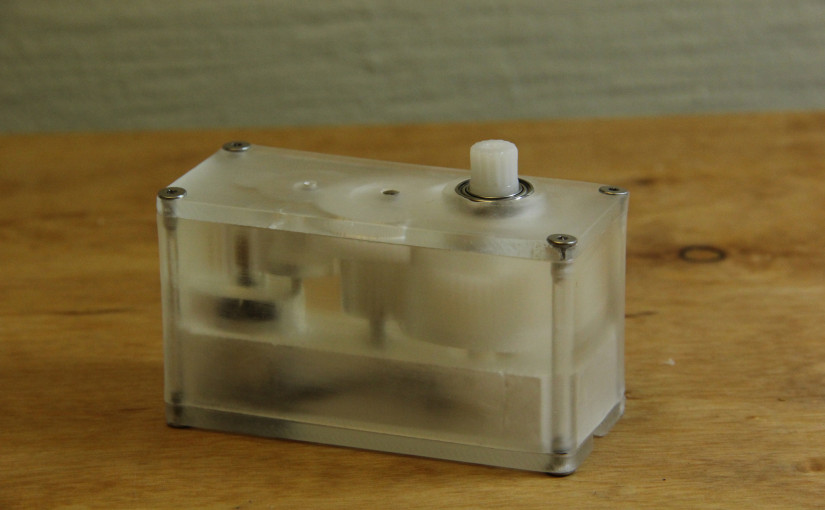

- I sanded and polished the final pieces with 600 grit sandpaper (wet) and Novus Plastic Polish so that I could see through the case. With only 20 minutes of work, I was able to see through, but it’s not a glossy finish that I could achieve with more work.

- I gave the gears a quick squirt of silicone spray before running them.

- The holes on the CAD file were sized for threading with a tap, but I ended up screwing in the screws directly before post-curing the parts in the sun.

I actually really like that the prints are still somewhat flexible after printing. I may capitalize on this feature and push the dowel-pins into their holes and then post-cure the resin to its complete hardness.

A quick note about the sound:

At low speeds, the motors give off a very audible whine. This shriek is from the PWM frequency of the electronic speed controller, currently at 8 KHz. When the motor starts to spin, the temporary electromagnets from the commutation sequence need to attract the rotor magnets. When they don’t cleanly commutate at low speeds, the stator magnets and rotor electromagnets snap together, causing the motor to vibrate more audibly at the PWM frequency and giving off that nasty, 8 KHz whine. I wonder if other motor controllers can pulse past the audible range…. Nevertheless, compared to the last transmission I made with these gears, which didn’t have an enclosure, the new transmission is far quieter and much more tolerable indoors.

The full parts list and the STL files are available after the break: